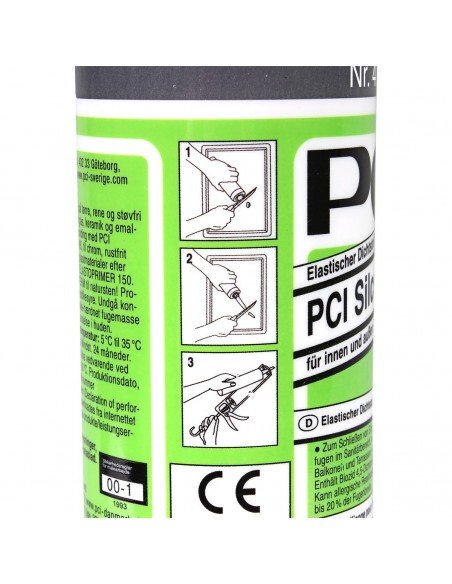

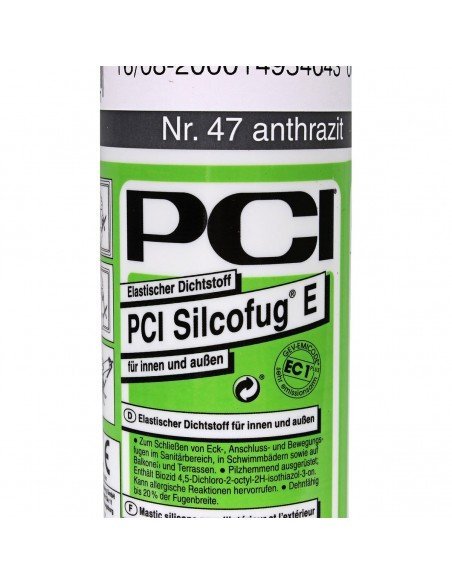

Elastic joint sealant PCI Silcofug ® E 310 ml

Amount of products available off-the-shelf. If order is placed before 3pm, it will be shipped same day with free next business day delivery.

Quantity available in stock for next day delivery:

- Colour: Anthracite pieces x 1

- Colour: Bahama Beige pieces x 1

- Colour: Black pieces x 1

- Colour: Jasmin pieces x 1 Anemone Anthracite Basalt Bahama Beige Beige brown Black Cement grey Carmel Dark brown Gray Intensive brown Jasmin Light brown Light gray Manhattan Midbrown Ochre Pergamon Red brown Sand grey Silver grey Topas White

In addition to that, we can deliver from our alternative warehouse within 3-4 business days.

- Colour: Anemone

- Colour: Basalt

- Colour: Beige brown

- Colour: Cement grey

- Colour: Carmel

- Colour: Dark brown

- Colour: Gray

- Colour: Intensive brown

- Colour: Light brown

- Colour: Light gray

- Colour: Manhattan

- Colour: Midbrown

- Colour: Ochre

- Colour: Pergamon

- Colour: Red brown

- Colour: Sand grey

- Colour: Silver grey

- Colour: Topas

- Colour: White

PCI Silcofug ® E 310 ml is an elastic joint sealant based on acetic acid for flexible jointing of ceramic and glass materials. Also to filling joints between those substates and other building elements. To use indoor and outdoor application, starting at walls and floor in bathroom, ending with swimming pools.

PCI Silcofug E biggest advantage is its versatility (can be used with many types of finish material, e.g. glass, ceramic, linoleum, stainless steel, etc.) and curing time - 2mm per day. Maximum joint width can be up to 30mm.

For joints 5mm wide and deep, PCI Silcofug E 310ml will cover up to 12.4 running metres. Product is avaiable in many colours.

Features and benefits:

- Elastic, capable of absorbing joint movement up to 20% (cf. IVD leaflet no. 2 - Classification of joint sealants).

- Resistant to weathering and UV radiation, ideal for outdoor application, temperature resistant up to +165 °C.

- Contains fungicides, prevents fungal decay and mildew growth on the joint sealant.

- Resistant to commercial household cleaners and disinfectants, the joint can be easily cleaned.

- Very low emission, GEV EMICODE EC 1 plus.

Fields of application:

- For indoor and outdoor use.

- For walls and floors.

- Sealing of corner joints, movement joints and connection joints in sanitary areas, on balconies and terraces.

- Sealing of joints between glass, aluminium, wood, enamel, ceramic, rigid PVC and sanitary acrylic.

- Sealing of glazing rebates at window frames made of wood, anodized and non-anodized aluminium (cf. DIN 18545 part 1-3 and IVD leaflet no. 10 - Glass sealing of wooden windows with joint sealants).

- Sealing of butt joints at figured glass, corrugated glass, glass blocks and elements.

- Material base

- silicone rubber, acid curing (acetoxy system)

- Components

- Single component

- Density

- approx. 1.0 g/cm³

- Packaging size

- 310 ml cartridges with srew-on nozzle. (One carton contains 12 cartridges)

- Shelf life

- min. 24 months when stored in dry conditions, no permanent storage over +30°C

- Joint width

- up to 30 mm

- 310 ml cartridge covers

- approx. 3.1 running metres for 10 x 10 mm joint • approx. 12.4 running metres for 5 x 5 mm joint

- 400 ml sausage covers

- approx. 4.0 running metres for 10 x 10 mm joint • approx. 16.0 running metres for 5 x 5 mm joint

- Time until skin forms

- approx. 10 - 15 minutes

- Total elongation allowed

- max. 20% of joint width

- Shore A hardness

- approx. 25

- Tensile modulus

- approx. 0.6 MPa

- Volume shrinkage

- approx. 6%

- Adhesion without primer

- to glass, ceramic, enamel, melamine resin, polyester, brick lining, non-vitrified pipes, sanitary acrylic, linoleum

- Adhesion with PCI Elastoprimer 150

- to Hostalit Z, glaze-coated open-pored wood, anodized and non-anodized aluminium, stainless steel, chrome

- Adhesion with PCI Elastoprimer 165

- to Hostalit Z, plasticized PVC, rigid PVC, PVC windows, rough-ground polyester

- Curing speed

- approx. 2 mm/day

Preparation of substrate

The joint sides must be dry, structurally sound and free from dust and other contamination. Remove oil stains and grease from non-absorbent substrates with PCI Univerdünner. Fill deep joints with closed-cell polyethylene backer rod. Be careful not to damage the backer rod during the application. A three-sided adhesion of the sealant to the bottom of the joint must be avoided. Backer rods containing bitumen or tar are not allowed to be used.

Application procedure

- All regular hand-operated and airoperated caulking guns (e.g. from Karl Dahm) are suitable for the application of PCI Silcofug E.

- Cut off tip of threaded nipple, screw on nozzle and cut off at an angle corresponding to the joint width. Fit cartridge into the caulking gun.

- Gun PCI Silcofug E into the joint using positive pressure to ensure full contact and adhesion. Tool to a bevel in corner joints.

- Smooth joint sealant before a skin forms using a suitable joint-shaping tool moistened with PCI Glättmittel. A skin forms within a few minutes. Work may be interrupted because new PCI Silcofug E perfectly bonds to a material which has already cured.

Please note:

- Paint does not bond to PCI Silcofug E (cf. IVD leaflet no. 12 - Overpaintability of movement-compensating joint sealants in building construction).

- PCI Silcofug E is not suitable for floor joints subject to heavy mechanical loads.

- Use PCI Carraferm for natural stone.

- The elastic sealing of movement joints and connection joints with PCI Silcofug E is not a substitute for required sealing measures in the substrate structure.

- See the technical data sheet no. 201 - PCI Elastoprimer for details on the application of PCI Elastoprimer 150 and 165.

- We recommend to test adhesion to and compatibility with lacquered and plastic substrates beforehand.

- Staining and bonding problems may occur in contact with mastic asphalt screeds.

- PCI Silcofug E might discolour when using cleaning agents and disinfectants which separate iodine.

- Minor colour variations are possible, it is therefore recommended to use the same batch number for the same project.

- Opened cartridges can be stored several days if the nozzle is plugged with some sealant. Remove the cured sealant from the nozzle before any further application.

- Although PCI Silcofug E contains fungicides, the joints should be cleaned with appropriate household cleaners and/or disinfectants in sanitary areas to prevent mould and mildew growth.

- Suitable tools are available e.g. from Karl Dahm Ludwigstr. 5 83358 Seebruck/Germany.

- Remove sealant spills with PCI Univerdünner while the material is still uncured. Cured sealant can only be removed by mechanical scraping.

02 Bahama beige

02 Bahama beige

18 Manhattan

18 Manhattan

31 Cement grey

31 Cement grey

03 Carmel

03 Carmel

19 Basalt

19 Basalt

40 Black

40 Black

05 Midbrown

05 Midbrown

20 White

20 White

41 Dark brown

41 Dark brown

11 Jasmin

11 Jasmin

21 Grey

21 Grey

43 Pergamon

43 Pergamon

12 Anemone

12 Anemone

22 Sand grey

22 Sand grey

44 Topas

44 Topas

16 Silver grey

16 Silver grey

23 Light grey

23 Light grey

47 Anthracite

47 Anthracite

49 Light brown

49 Light brown

50 Red brown

50 Red brown

51 Intensive brown

51 Intensive brown

52 Beige brown

52 Beige brown

53 Ochre

53 Ochre

Subject to deviations in colour due to print.

Certified Trust and Exceptional Service

Since obtaining our Trustmark on 18 May 2015, wetroomsdesign.co.uk has consistently demonstrated its

commitment to being a trustworthy online retailer. Our excellent customer reviews are a testament to

our focus on rapid delivery, facilitated by our UK-based warehouse. Stocking thousands of products

available for next-day delivery ensures that you receive your purchases promptly. Additionally, our

dedicated customer service team is always ready to assist you during and after your order, enhancing

your shopping experience. With Trusted Shops Buyer Protection up to £2,500, every purchase is

securely backed, ensuring peace of mind with every transaction.

Product Reviews This tab features detailed reviews of the product you are viewing, offering firsthand insights from customers who have experienced its benefits. While the product available on this page may have similar features to other items in our range, each review specifically addresses this particular model, which is available in various sizes to suit diverse needs and preferences. These reviews provide valuable information to help you make an informed decision, highlighting the distinct characteristics and quality of each product uniquely available here.