This installation guide shows steps how to install wet room kit shower tray Showerlay Wiper into a concrete floor how to tile it over.

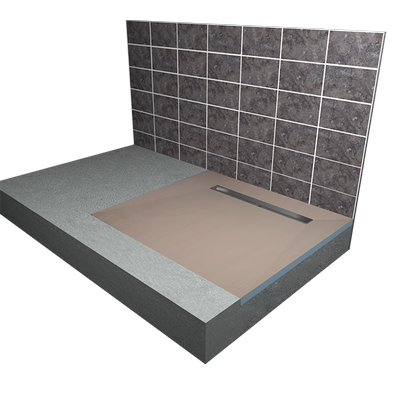

This installation guide has the steps needed to install your wet room kit shower tray. Showerlay Wiper installation into a concrete floor and how to tile over it. The materials used to produce your shower tray comprise of a foamed based XPS tray with a preformed 1%-2% slope and an integrated grade 304 stainless steel linear or square drain. The tray is waterproofed, reinforced with a microfiber mesh and coated with a cementitious glue.

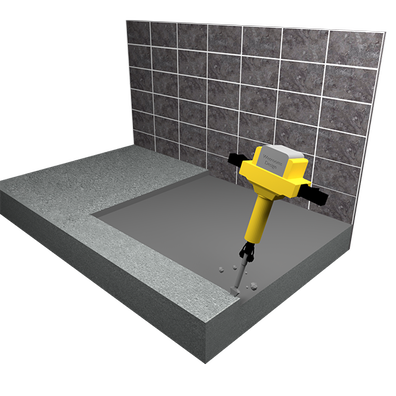

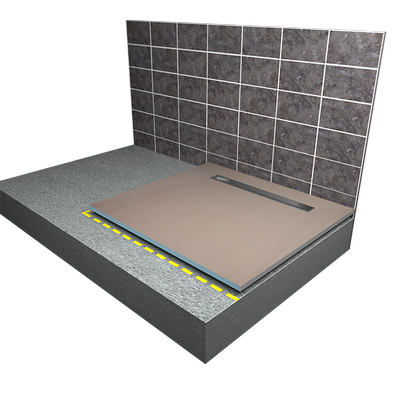

Your Showerlay preformed tray will be 20, 28, 30, 35 or 40 mm thick. The thicker the tray, the greater and more noticeable the gradient slope will be. The top edge of the tray will need to be flush with the surrounding subfloor once installed, so you will need to dig into the concrete to the same depth as the thickness of the tray you have. Depending on the model of tray you have, means the integrated drain could be raised above the top base of the tray or flush with it. Be sure to lay your finish evenly across the tray and subfloor to ensure you have no uneven height increase.

We supply all of our Showerlay trays with a standard HC26 waste trap, but you can request a different waste trap from the selection we have on offer at no extra cost. Tanking kits can be purchased with your Showerlay tray. Each tanking kit covers a 3.5 m² area, which will waterproof your shower area. It is highly recommended that you waterproof your shower room to protect from any potential leakage through your finished tile work against water damage. Additional sealing materials found in our tanking kits can be purchased separately in the ‘Sealing Membranes’ and ‘Insulation Chemical’ category in our store.

Waterproofing your surrounding concrete floor before covering it with tile is recommended. Sealing the concrete can prevent condensation and protect both your subfloor and tiles. This means your tile stays dry and thus reduces the chance of mold and mildew. A more in-depth guide to waterproofing is available on our DIY insulation guide page.

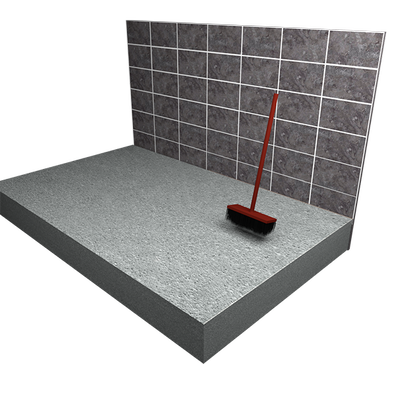

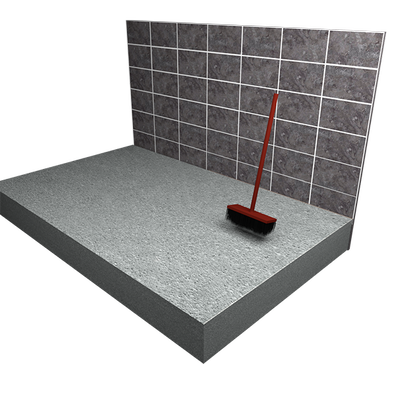

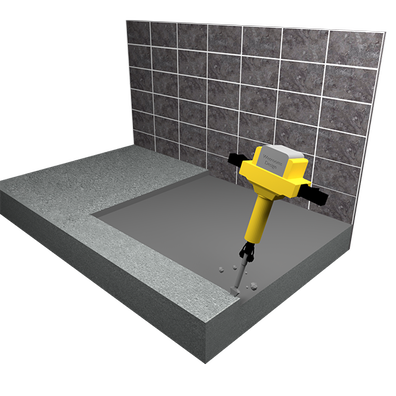

1. Prepare your floor and walls by removing any debris and dust. Clear your work space and prepare the required materials and tools for installation of your Showerlay tray. The tools you will require are as follows: spirit level, chisel & hammer or jackhammer, pencil, tape measure, paint brush or roller, notched trowel, tile adhesive .Your Showerlay tray can be trimmed down to size if required. We recommend using a good quality handsaw if trimming is carried out. The tray should be trimmed equally on both sides to maintain symmetry on the slopes leading to the integrated drain on your tray.

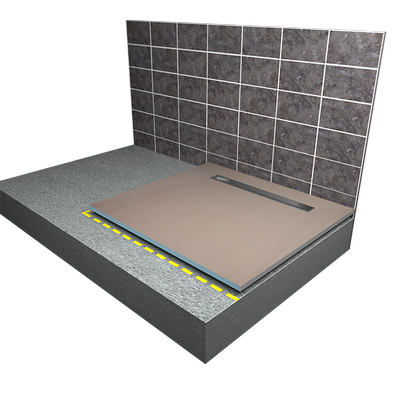

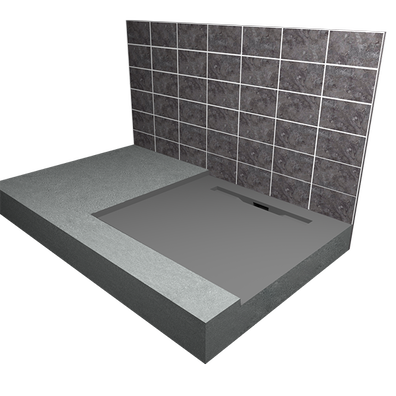

2. Establish the position you need your Showerlay tray to be installed by placing it on top of the existing concrete. Make sure the tray is secure whilst you use a pencil to draw around the perimeter and also inside the drain outlet to mark the position of the waste trap. If you’re bedding the tray on top of the existing concrete and plan to screed the surrounding floor, skip the last part of step 3 and only dig out the required space for the waste trap and pipe work.

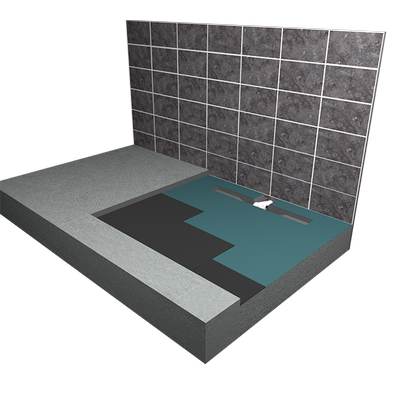

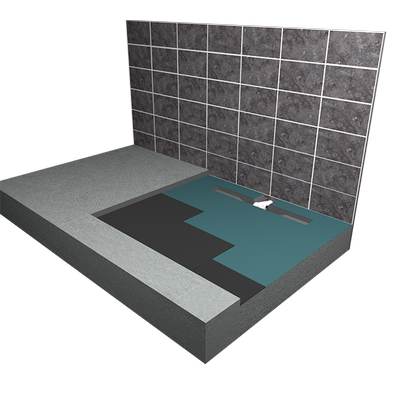

3. Using the position of the marked outlet, dig a total depth of the thickness of your tray and a further 68 mm to accommodate space for your waste trap and piping. Using the tray perimeter you have drawn, remove the existing concrete to the depth of your Showerlay tray using a chisel and hammer or jackhammer. Take note of the integrated drain position on the underside of the tray. Depending on the thickness of your tray, could mean the underside of the drain sits proud a few millimeters below the tray. In this case you will need to create space in the concrete so the tray can be bedded evenly.

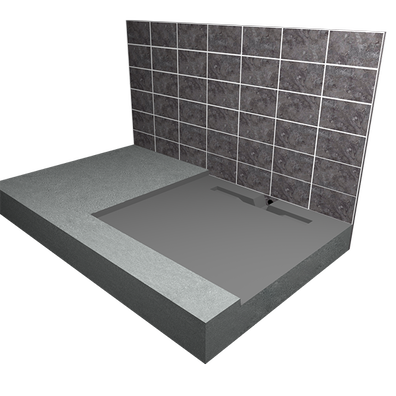

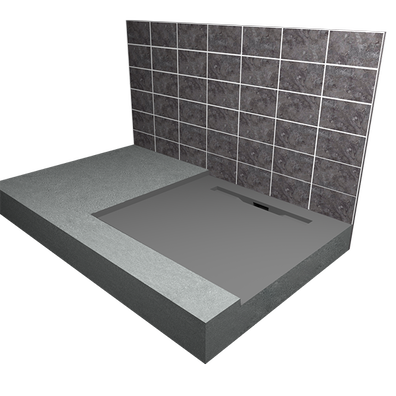

4. Find the best possible position and angle to connect the waste trap to your pipe work. The waste trap can be rotated 360° and the waste trap compression fitted adapter can be used to adjust the height of the connected pipe work. Ensure the waste trap is supported beneath with concrete. If the space is too deep, build up the needed support with more cement.

5. Connect your standard 40 mm pipe to the waste trap compression adapter. Ensure you fit the waste trap in a position which is aligned with the outlet of the Showerlay trays integrated drain once the tray is bedded. Once you are sure the waste trap is well supported and happy with the connected pipe position, perform a water test to be sure there is sufficient flow.

6. Prepare the tray slot now. Ensure the surface is clear of debris and dust. Your Showerlay tray needs a solid, even surface for support. If the surface has cracks, holes or is uneven, use a floor leveling compound to create a thin layered fixing surface. Once completed, use a spirit level to ensure the surface is even.

7. Test the positioning of your Showerlay tray. Ensuring it will be flush with the surrounding subfloor once bedded and that you can connect the waste trap to the drain outlet. Use a spirit level to make sure the tray is level and the gradient slope to the drain is the lowest point on the tray.

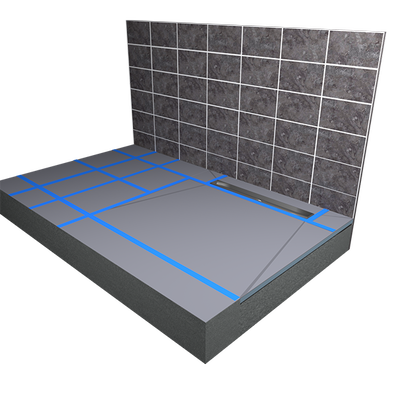

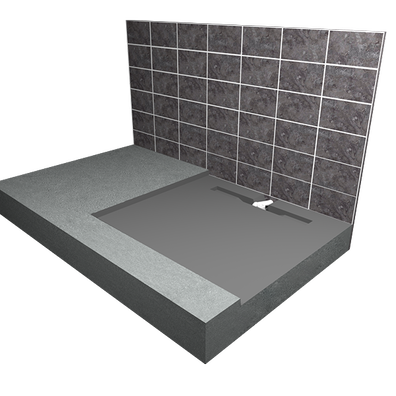

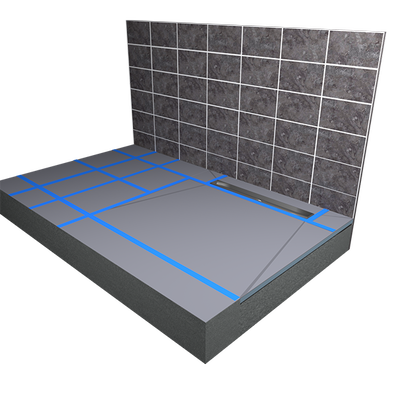

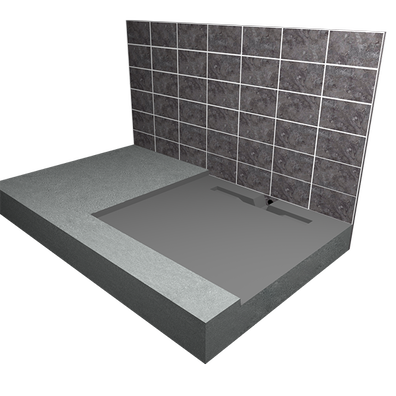

8. Using good quality tile adhesive and a notched trowel, evenly apply 0.5 – 1 mm over the entire concrete area where your tray will lay. Insert your tray in the concrete slot and attach the waste trap to the drain outlet, using the provided screw fixture and then silicone to seal. Your Showerlay tray should now be flush with the surrounding concrete subfloor. Once complete, use a spirit level to check the tray is laid correctly and flush in its slot.

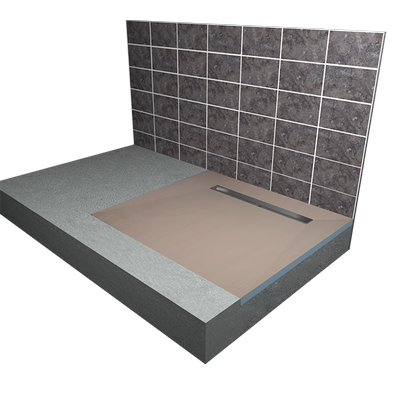

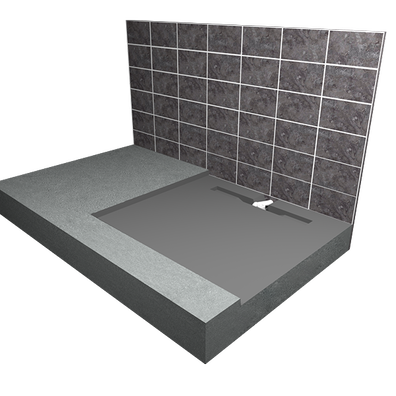

9. Depending on the model of tray you have, means the integrated drain could be raised 15 – 20 mm above the base of the tray or flush with it. If the integrated drain is raised, you will need to ensure the top edge of your tile is flush with the top lip of the drain channel. If you need to build up space beneath your tile to make it flush with the drain, you can use tile backer boards. Backer boards are not only good for building up space, but also used for waterproofing floors and walls. Once laid, using membrane sealing tape and PCI lastogum found in our waterproofing kit, seal the edges of the boards, edges between the wall and floor corners and also the tray to fully waterproof your wet room.