- Adam

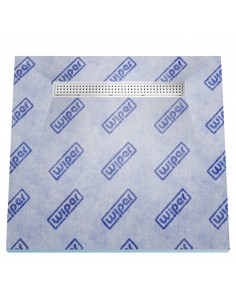

- Shower drains

- 3123 views

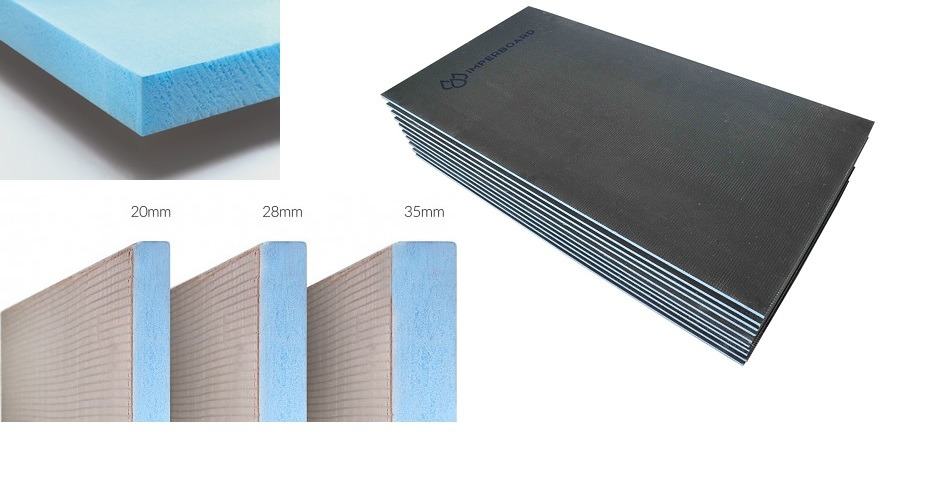

XPS - Extruded polystyrene foam

Extruded polystyrene called styrodur (abbreviated as XPS) is a thermal insulation material, formed into a plate by extrusion and direct foaming. It is produced on the basis of a polystyrene resin, a safe material for health, approved for contact with food. The structure is characterized by a specific fine-and closed-cell structure of the foam containing the air in the structure, thanks to which it is very light. It has similar applications to standard styrofoam. However, the production process of an XPS board is more complicated than styrofoam (EPS) and has different properties. It is characterized by much greater hardness and mechanical strength than an EPS board. It's easy to distinguish it from ordinary styrofoam, because the XPS board is colored - it can be blue, green or pink. It is also almost twice as expensive.

The most important advantages of the product are its mechanical properties and high resistance to moisture.

Due to the excellent XPS immunity to moisture, both through prolonged immersion in water and long-lasting diffusion as well as absorbability resulting from freezing and thawing cycles, XPS products retain their invariable, excellent thermal insulation parameters over a long period of time. As a result, the products have been used for many years as thermal insulation in such demanding building applications as a reverse layer roof, insulation of basement walls from the outside or floor insulation on the ground.

Another advantage is the smooth surface and easy installation of XPS boards. In addition, it is a self-extinguishing product, and at the same time is fully recycled, which affects the protection of the natural environment. As a result, XPS polystyrene foam products are most often used as thermal insulation.

XPS boards can not be used in direct contact with substances that destructively affect polystyrene (eg organic solvents such as acetone, benzene, nitro). or other preparations containing such organic compounds.

It is recommended to use solvent-free adhesives for installation of boards. Before use, check whether the adhesive can be used for polystyrene foam. Installation at low ambient temperatures requires free space between the boards to maintain proper dilatation.

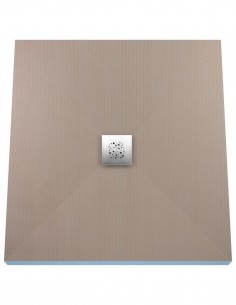

We use such good properties to create reliable wet rooms. Shower trays made of XPS foam, covered with two-layer cement glue and prepared slopes towards the drain are ideally suited for wet rooms.

XPS foam is a modern material widely used in construction for thermal insulation of foundations, basements, inverted roofs and places exposed to constant contact with moisture. The material is characterized by a closed cell, homogeneous structure in its entire mass, which guarantees maintenance of its insulating properties in the long-term. XPS boards are ecological and environmentally friendly. In our Wetrooms Design Ltd store you will find shower trays and tile boards made of XPS foam.